- Download

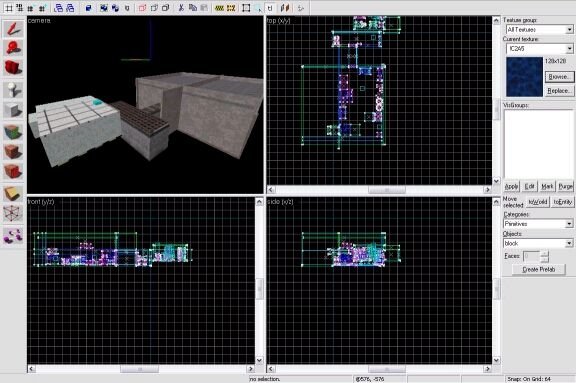

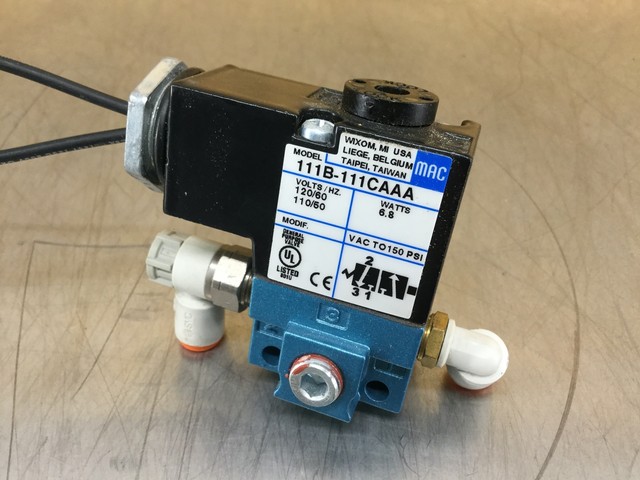

Source is a 3D game engine developed by Valve.It debuted as the successor to GoldSrc with Counter-Strike: Source in June 2004, followed shortly by Half-Life 2 in November, and has been in active development since. Source does not have a concise version numbering scheme; instead, it is designed in constant incremental updates. The successor, Source 2, was announced in March 2015. Run through equipment cycles up to 30% faster than with standard valves. These valves shift between flow positions in 1. Often used to extend and then retract a cylinder at different speeds, they create two actions and have two exhaust ports, which allows you to control the speed of each action by attaching a flow control valve to each exhaust port. Hammer is a great way of building out HTML websites. With features including HTML includes, SASS, and CoffeeScript parsing and clever paths, Hammer is an indispensable tool! Hammer has some built in features that happen automatically, and some clever functions you use with special hammer tags. HTML Includes - Front-end developers shouldn't have to run local server environments, or use PHP just. Make offer - ingersoll rand, hammer case assembly, for i-r 285a 1' impact wrench Ingersoll Rand 3940-D727 Hammer Case Housing Titanium 3940B2Ti 1' Impact $500.00.

Often downloaded with

- Hammer Heads Deluxe (verwijderen)In this original, colorful, and altogether smashing game, the gnome population,...$9.99DOWNLOAD

- DJ OldGames Package: Hammer of the GodsThe journey may scar your soul, cost you family and friends, but it will also...DOWNLOAD

- Sledge EditorThe purpose of Sledge is to offer advanced editing features from later versions...DOWNLOAD

- KORG M50 EditorKORG M50 Editor is a brilliant new synthesizer distilling the sonic essence and...$200DOWNLOAD

- InstruCalcInstruCalc calculates the sizes of control valves, flow elements, and relief...$2395DOWNLOAD

Directional-control valves are vital in any pneumatic circuit, directing or blocking airflow to control the speed or sequence of operations. One method of classifying directional-control valves is by the flow paths under various operating conditions. Important factors are the number of possible valve positions and the number of ports and flow paths. Here are some basic configurations.

| Download this article in .PDF format This file type includes high resolution graphics and schematics when applicable. |

Three-way valves direct pressurized air to the cap-end side of the cylinder. Shifting the spool to the other extreme position blocks flow and pressure to the actuator. The actuator is connected to the exhaust passage, therefore spring force or gravity must return the rod to its original position.

Three-way valves may also be used in pairs to operate a doubleacting cylinder, thus replacing a four-way valve. Consider using paired three-way valves instead of a four-way when high cylinder speeds are necessary. Close coupling of three-way valves to the cylinder ports reduces cylinder back pressure and pressure drop in the lines, permitting higher cylinder velocities. The valves are also used to save compressed air in highly cyclic applications or when intermediate positions are required.

The five-port version of the two-position, four-way valve has five individual ports which provide various valve configurations such as two different exhaust or pressure ports. In the latter case, for example, the valve might supply high pressure to actuate a cylinder and provide high clamping force, but deliver lower pressure (from a regulator) to release the clamp. Using lower pressure conserves energy.

Hammer Blind Valve

Four-way, three-position valves are also available in five-port versions. The most common center conditions for these valves are 'all ports blocked' and 'exhaust center.' The two extreme positions of the four-port, four-way valve are the power positions of the valve which control actuator movement. The center position is designed to satisfy some system requirement such as locking an actuator or letting it float.

Valve Hammer Editor 3.4 Download

This is just a brief look at directional valves and other factors, such as the basic valve design, should be considered when constructing pneumatic systems.

Valve Hammer For Mac Pro

Information for this article provided by the Pneumatics Div. of Parker Hannifin, Richland, Mich. For more details, visit www.parker.com/pneumatic